Metal Castings: Choosing Between Sand, Die, or Investment Casting

Wiki Article

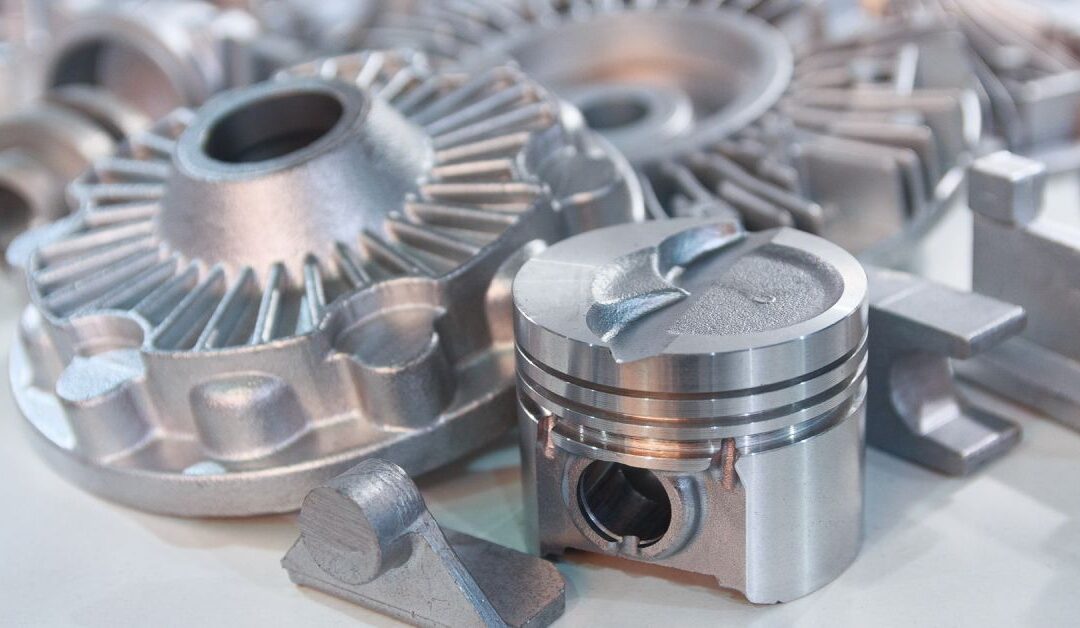

Discover the Flexibility of Aluminum Castings: Crucial Facts and Solutions You Need To Know

Aluminum spreadings are progressively acknowledged for their versatility throughout different sectors. Their lightweight nature, corrosion resistance, and strength-to-weight proportion make them a recommended choice in many applications. From vehicle to aerospace, the convenience of these castings is amazing. Yet, the approaches of manufacturing and the variety of solutions offered often go unnoticed. Understanding these elements can substantially influence task results and efficiency. What vital realities and services should one consider when exploring light weight aluminum castings?The Characteristic That Make Aluminum Castings Perfect for Numerous Industries

Light weight aluminum spreadings have an one-of-a-kind combination of buildings that provide them remarkably suitable for a variety of industries. Their lightweight nature is just one of the most considerable advantages, enabling easier handling and reduced transportation costs (Aluminum Castings). Light weight aluminum castings also exhibit outstanding corrosion resistance, which prolongs the life-span of components in challenging environments. Additionally, they provide excellent thermal and electrical conductivity, making them excellent for applications needing reliable warmth dissipation or electrical links

Usual Applications of Aluminum Castings

Additionally, the electrical market frequently employs aluminum castings for real estates and rooms, helping with effective heat dissipation and enhancing security. The customer items sector utilizes light weight aluminum castings in products such as kitchenware and furniture, where looks and performance are paramount.

The marine sector depends on light weight aluminum castings for parts that sustain extreme settings, such as boat hulls and installations. On the whole, light weight aluminum castings serve a wide range of functions, showcasing their flexibility and necessary function in contemporary production processes.

Different Casting Methods Explained

Recognizing the different casting approaches is crucial for choosing the appropriate method for light weight aluminum spreadings. 2 popular approaches, sand casting and die spreading, deal unique benefits and applications. Each approach's one-of-a-kind features affect the end product's high quality and suitability for details uses.Sand Spreading Process

While various casting methods exist, sand spreading stays among one of the most widely made use of methods due to its flexibility and cost-effectiveness. This process includes creating a mold and mildew from a blend of sand and a binding representative, which forms the cavity right into which liquified light weight aluminum is put. The sand mold and mildew can be easily formed and recycled, allowing for the production of complicated geometries. Once the light weight aluminum solidifies, the mold and mildew is broken away, disclosing the actors component. Sand spreading is specifically ideal for reduced to medium manufacturing quantities, making it excellent for customized elements. Its adaptability to various shapes and sizes, combined with the capacity to accommodate detailed designs, even more improves its appeal in numerous industries.Pass Away Spreading Techniques

Pass away spreading represents a distinct technique in the area of aluminum spreading methods, supplying high accuracy and efficiency for automation. This technique entails requiring liquified aluminum right into a mold and mildew under high pressure, making sure a high-grade surface and tight tolerances. There are 2 key kinds of die casting: hot chamber and cool chamber. Warm chamber pass away casting appropriates for low melting factor alloys and enables for fast manufacturing cycles. In comparison, cold chamber pass away casting is used for materials with higher melting points, needing the aluminum to be ladled into the chamber. Both methods enable the production of complex forms and complex styles, making pass away casting a popular option for industries such as automotive, aerospace, and customer items.Benefits of Making Use Of Aluminum Castings

Various benefits make light weight aluminum spreadings a preferred option across numerous sectors. To start with, aluminum's lightweight nature significantly minimizes the overall weight of products, enhancing their efficiency and efficiency. Additionally, aluminum spreadings show excellent rust resistance, which extends item life expectancy and decreases maintenance prices. The product's high thermal and electric conductivity also makes it suitable for applications in vehicle and electronic devices sectors.Furthermore, light weight aluminum spreadings can be generated with detailed designs, allowing producers to create complex shapes that meet particular demands. This versatility not just sustains cutting-edge designs however also reduces the demand for added machining processes, saving time and resources. Light weight aluminum's recyclability straightens with sustainability goals, appealing to eco aware organizations. Collectively, these benefits position aluminum spreadings as a superior option for a large range of applications, making certain toughness, effectiveness, and cost-effectiveness in today's affordable market.

Providers Offered by Light Weight Aluminum Casting Manufacturers

Furthermore, they usually supply different casting methods, such as sand casting, pass away spreading, and financial investment casting, each matched for various task demands. Quality assurance is an additional important solution, with makers carrying out rigorous testing and assessment procedures to assure that spreadings fulfill sector standards.

Moreover, aluminum casting business usually assist with completing services, including machining, surface area treatment, and finish, boosting the final product's resilience and visual allure. They might supply logistical support, guaranteeing prompt delivery and effective supply chain administration to meet client due dates.

Tips for Selecting the Right Light Weight Aluminum Spreading Partner

Picking the Wisconsin Aluminum Foundry right aluminum casting companion can significantly influence the success of a job (Wisconsin Aluminum Foundry). To ensure compatibility, business ought to initially analyze the partner's sector experience and technical expertise. A service provider with a solid history in specific applications can offer innovative options and beneficial insightsNext off, it is essential to review the quality assurance procedures in area. A dependable partner will certainly follow rigorous high quality criteria and provide certifications where relevant. Furthermore, evaluating past tasks and client endorsements can offer a clearer understanding of the partner's abilities and integrity.

Cost-effectiveness is additionally crucial; nevertheless, it must not compromise top quality. Business must seek an equilibrium in between price and the degree of solution provided. Ultimately, open communication and responsiveness are vital features. A partner that prioritizes partnership cultivates an effective working connection, ultimately resulting in successful job results.

Often Asked Questions

Can Aluminum Castings Be Fixed if Harmed?

Yes, aluminum spreadings can be repaired if damaged. Aluminum Foundry. Methods such as welding, brazing, or glue bonding are typically employed, relying on the level of the damage and the certain needs of the repair service processExactly How Do Aluminum Castings Compare to Various Other Steels?

Aluminum spreadings are lighter, corrosion-resistant, and a lot more malleable compared to other steels like steel or iron. Their excellent thermal conductivity and recyclability make them a recommended selection in various sectors, enhancing versatility and performance.What Is the Lifespan of Aluminum Castings?

The lifespan of light weight aluminum spreadings commonly varies from 10 to 50 years, depending upon environmental conditions, alloy composition, and application. Proper maintenance and protective steps can greatly boost their resilience and long life in different setups.Are Light Weight Aluminum Castings Recyclable?

Yes, aluminum spreadings are recyclable. They can be thawed down and repurposed without losing their inherent residential or commercial properties, making them an eco-friendly choice. This recycling procedure adds to sustainability and decreases the need for new aluminum manufacturing.Just how Do I Keep Light Weight Aluminum Castings?

To keep aluminum castings, one ought to consistently clean them to get rid of dirt and oxidation, use protective finishes to avoid deterioration, and examine for damage to assure long life and structural integrity in different applications.The flexibility of light weight aluminum spreadings allows their prevalent usage throughout different markets. Recognizing the various casting techniques is necessary for selecting the proper method for aluminum castings. Die spreading represents a distinct strategy in the field of light weight aluminum spreading strategies, providing high accuracy and effectiveness for mass production. Numerous advantages make light weight aluminum spreadings a favored choice throughout numerous markets. In addition, they typically provide different casting methods, such as sand casting, pass away casting, and investment casting, each suited for various project demands.

Report this wiki page